Gas Land recently visited Adriatic LNG to service four Nitrogen Generators that are running on the platform. Adriatic LNG terminal is a LNG receiving facility located in the Adriatic sea offshore of Porto Viro. Ten years ago, the Nitrogen Systems were designed to run three systems at all times, and use the fourth system as a backup. However, today the terminal is using one system continuously to meet normal demand requirements, and use all four systems during peak demand. Currently, each system produces about 200 - 220 Nm3/hr of Nitrogen at 98% purity. Gas Land worked with Adriatic LNG to further fine tune performance for each system such as monitoring DCS and recommending maintenance and spares, along with expanding the system's life for another 10 years.

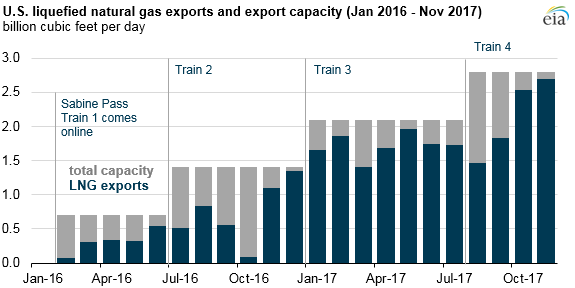

Adriatic LNG is the world's first offshore gravity based structure LNG regasification terminal. The terminal mainly imports LNG from Qatar but also receives cargoes from Egypt, Trinidad and Tobago, Equatorial Guinea and Sabine Pass from the United States, all of which have Gas Land's Nitrogen Systems.