The Optimized Cascade Process is one of the most extensively used process in major Liquefaction plants worldwide. From Sabine Pass Louisiana to Queensland's LNG plants in Australia, the Optimized Cascade Process has been used for over four decades. This technology is based on three multi staged , cascading circuits using pure refrigerants (Propane, Ethylene and Methane). Other key features include use of Brazed Aluminium Heat Exchangers and insulated Cold Box Modules. Heat Integration in the process has been modified such that it approaches Natural gas and Refrigerant cooling curves which results in high efficiency. The use of Brazed Aluminium Heat Exchangers and Cold Box Modules allows for efficient heat transfer which can serve a wide range of LNG plant sizes. Depending on the Feed Gas characteristics a HRU and NRU option can be integrated in the process to further optimize the plant performance. The table below shows a list of current and under construction LNG plants that would be using the Optimized Cascade Process for liquefaction of natural gas.

Australia Pacific LNG

Courtesy: Australia Pacific LNG Plant

Australia’s LNG boom can be attributed to the three simultaneous construction programs: Queensland Curtis LNG, Santos GLNG, and Australia Pacific LNG - which are part of the largest concentration of private capital investment in its history. When in operation of Q4 2016, the three plants would have a combined capacity of 25 million tons of LNG per annum. Out of the three, Australia Pacific LNG was the largest LNG plant to commence construction. It consists of a two train LNG facility with the potential for additional two trains. The plant is capable of producing a staggering nine million tons of LNG per annum.

The coal seam gas for Australis Pacific LNG is sourced from fields in the Surant and Bowen basins in South West and Central Queensland. The gas then enters a 329 mile gas transmission pipeline to reach the Curtis LNG facility where it is liquefied. When the gas is cooled to liquid, the volume of the gas is reduced by 600 times, this liquefaction allows the gas to be shipped and stored safely.

Australia Pacific LNG is a joint venture between Origin (37.5%), ConocoPhillips (37.5%) and Sinopec (25%). This facility uses the ConocoPhillips Optimized Cascade Technology to process coal seam gas into Liquefied Natural gas. Bechtel was awarded the EPC contract for the two train LNG facility.

Each train is made up of Prefabricated Modules, Structural Steel, Piping Systems, CO2 Absorber, Refrigerant Cold boxes and Gas Land’s very own Nitrogen Generation Systems with Liquid Nitrogen Systems as a backup. Recently, Gas Land successfully commissioned Train 2 in July 2016. The system was performing to design delivering better than the promised flow and purity.

LNG Chain – The Optimized Cascade Process

Courtesy: ConocoPhillips Website

Making LNG involves liquefying natural gas for storage. To achieve this, first the feed gas must be treated to remove impurities such as CO2 and Water. The goal of the process is to increase methane concentration and to remove all impurities before liquefaction.

Let’s study the main equipment utilized in this process.

1. Auxiliary Oil Heater – This is an important component for the LNG process which provides the initial heat to the gas exchangers.

2. Acid Gas Removal Unit (AGRU): It removes sour gas from the feed gas before it enters the cooling phase.

3. Dehydration: From the AGRU the gas now moves to the dehydration unit where any remaining water is removed so it does not form ice when liquefied.

4. Mercury removal units: It is crucial to remove mercury primarily because of its corrosive nature on aluminum before it enters the cooling stage.

5. Compression: Gas is progressively compressed through the ConocoPhillips Optimized Cascade process. The gas is forced through by one of two independent compressors.

6. Cold Boxes: Propane, Ethylene, Methane are used as the three refrigerants to liquefy the natural gas to liquid. The cooling process takes place in the Cold Box’s within each train. It contains a cryogenic brazed aluminum heat exchanger.

7. Inlet Air Chilling: All the three Curtis Island projects have inlet air chilling on each gas turbine to boost compressor driver power in order to maximize LNG production.

The main highlights of the Optimized Cascade Process can be summarized as follows

- Two trains in one configuration yields higher plant efficiency

- Can handle a broad range of plant ambient temperatures and feed compositions

- Flexible operations which enable easy start up, shutdown and maintenance

- Use of Brazed Aluminum Heat Exchangers, Aeroderivative Gas Turbines with Waste Heat Integration leading to higher thermal efficiency.

Coal Seam Gas vs Shale Gas

Courtesy: Australia Pacific LNG Website

Coal Seam Gas is primarily methane, which is colorless and odorless found in coal deposits. Natural gas collects in underground coal seams at depths of 300m to 1000m underground. It is sometimes referred to as coal bed methane (CBM) and would be classified under the umbrella of Unconventional Resources. The difference between conventional and unconventional gas is the geology of the reservoirs from which they are extracted and which therefore require different extraction techniques. With coal seam gas comprising mostly of methane, it has a much more simplified approach in drilling, production, storage and separation techniques when compared to producing shale gas in the US. Natural gas can get collected underground in coal seam beds by bonding to the surface of coal particles. These coal seams are generally filled with water. Interestingly, it is the pressure of the water that keeps the gas attached as a thin film to the surface of coal particles.

Like any other formation, a well is drilled to the required depth to access the coal seam gas, Origin, which is the upstream operator in Australia, uses hybrid drill rigs to obtain efficiency. The completion of the well enables some water to be pumped to the surface. Since the water is pumped to the surface the pressure within the formation is reduced which helps the gas to flow to the surface.

What’s intriguing is that hydraulic fracturing is not always required. Undoubtedly, this depends a lot on the formation itself but most of the current coal seam gas production serving Australia Pacific LNG is coming from high flowing wells, which are not hydraulically fractured. In comparison to US shale, to produce from shale plays such as Texas or North Dakota, hydraulic fracturing is a must because the formation is so tight. Without hydraulic fracturing of these shale plays production is not economical. Another key characteristic of hydraulically fractured wells in the US is that production is high for the first 6 months to a year and then drops rapidly. Many scholars have linked this decline to the closing of fractures and the natural decrease in the reservoir pressure of the formation due to production

Typical Nitrogen Generation Plant

Nitrogen forms a critical component of the utility system as it is used for various applications in a LNG Plant. Nitrogen is mainly used for purging, blanketing, and as a seal gas for various compressors and pumps. The above figure depicts a typical Nitrogen Plant set up upstream and downstream of the Nitrogen Generator. The Nitrogen is distributed to various trains, or users via the Nitrogen Distribution Header. A secondary Nitrogen Generation system such as the Liquid Nitrogen Storage & Vaporization package or another Membrane Nitrogen Generator is generally used as a backup system.

Sabine Pass Liquefaction & LNG Export

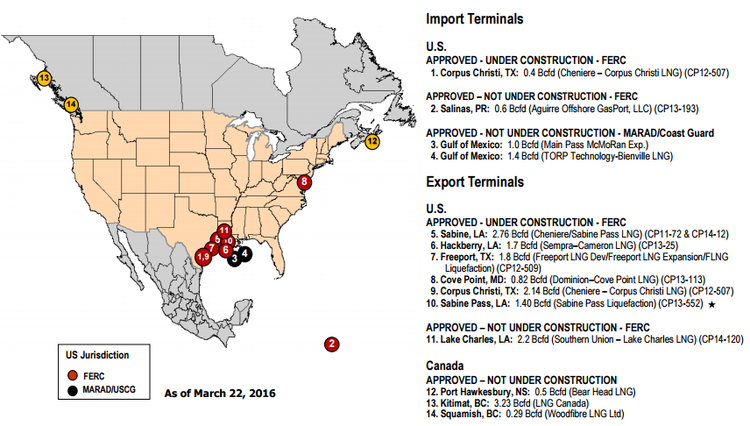

Sabine Pass is the first liquefied natural gas export terminal to be constructed in the lower 48 states. Owned and operated by Cheniere Energy, a Houston based company, is primarily engaged in LNG related businesses.

Located in Cameron Parish, Louisiana, Sabine Pass has completed construction of the first two of its six liquefaction trains. Each train has a capacity to liquefy 0.55 billion cubic feet per day (bcfd) of natural gas. Once all 6 trains are up and running, the plant would have a staggering capacity of 3.3 bcfd. In other words, each liquefaction train is expected to have nominal production capacity close to 4.5 million tons per annum (mtpa) of LNG. Three other trains at Sabine Pass are currently under construction, which are scheduled to come online in 2017-2019. Decision on financial investment on the sixth train is still awaiting approval. Through its owned subsidiary Cheniere Creole Trail Pipeline, Cheniere also owns a 94 mile pipeline that connects Sabine Pass LNG terminal with a number of large interstate pipelines.

Globally, six other liquefaction projects are scheduled to come online this year in Australia, Indonesia, and Malaysia. Together they would approximately add 8% to the global liquefaction capacity, while just the two trains at Sabine Pass would add 2% to the total.

The future of LNG production facility in the US looks extremely promising. Although one would argue that the current slump in oil price has stalled developing projects. LNG export facilities currently under construction in the US including Sabine Pass will have a total liquefaction capacity of 9.2 bcfd which is equivalent to 13% of current domestic natural gas production. Once all facilities under construction become operational, which is expected to happen somewhere around 2020, the US would possess the third largest liquefaction facility in the world after Australia and Qatar.

Courtesy: EIA